Lost Foam Casting

Why Choose Lost Foam Casting?

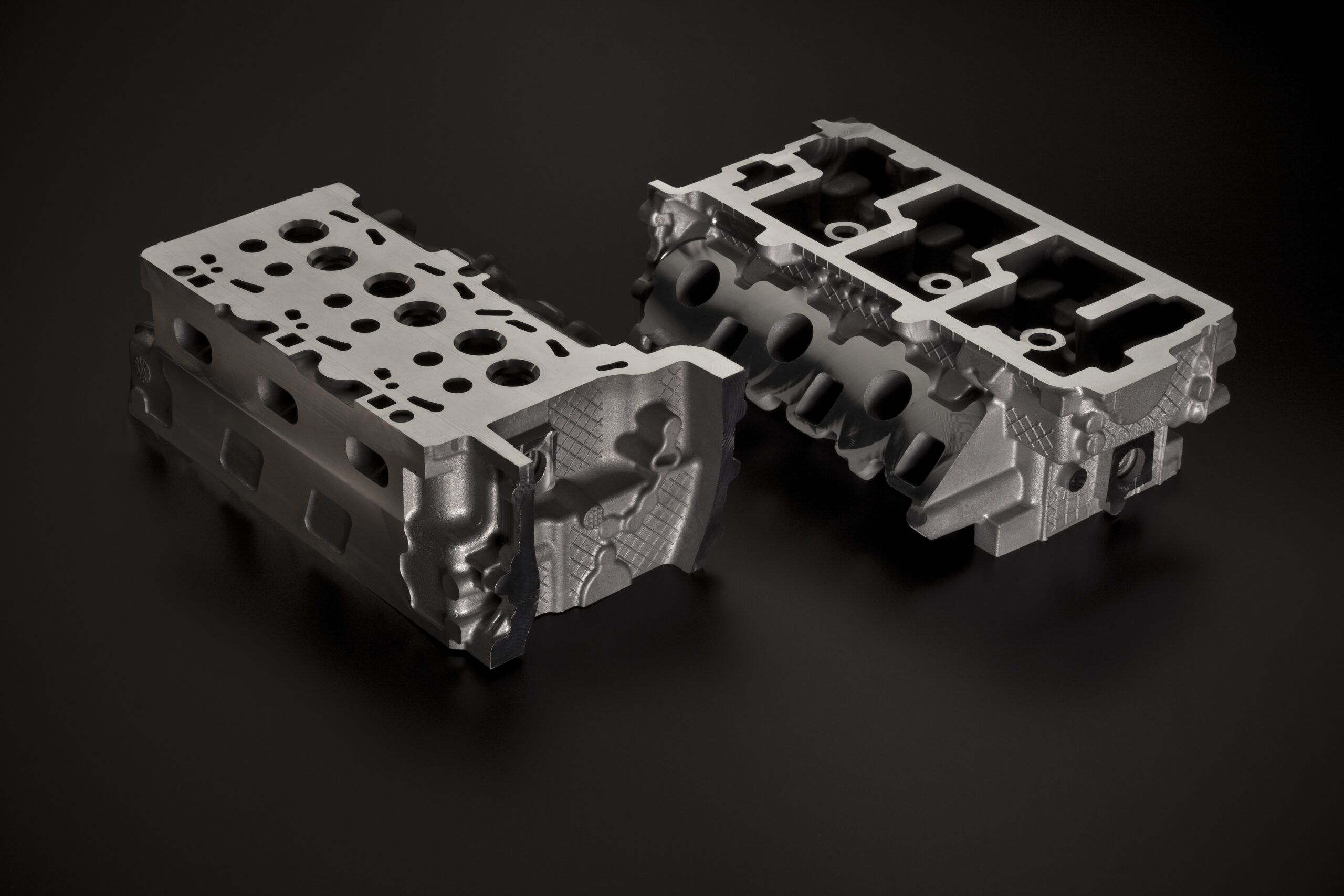

The Lost Foam Casting Process(LFC) is the most modern and innovative technique available on the market today. Lost Foam Casting is a process used to create complex metal pieces and parts in which molten metal evaporates into a foam mould while still being held with sand.

The first step of Lost Foam Casting is the creation of the foam mould. A block of polystyrene foam is cut into the exact shape of the finished product using hand or power tools. For applications where the dimensions of the finished piece must be exact, power tooling is preferred for a more consistent shaping of the foam.

For designers, the Lost Foam Casting Process(LFC) offers unique freedom in design, because the polymer foam patterns can be composed of several parts and allow for significantly more complex constructions than other moulding tools.

WELD2CAST’s Lost Foam Casting Benefits Include:

- Use in precision casting of ferrous and non-ferrous metals.

- Suitable for castings between 1 kg – 200 kg.

- Cost effective – fewer actions are required compared to Investment Casting (water glass) therefore providing cost effectivity.

- Weight reduction – high dimensional accuracy is attained, and thin sections can be cast with a wall thickness to 3.0 mm.

- Excellent surface finish, typically from 25µm can be achieved.

- Multiple castings can be combined in one mould to increase pouring efficiency.

- Foam casting requires no draft to aid removal from the mould.

- Very environmentally friendly – energy-efficient casting process with low emissions and closed mould material circulation.