Casting Matrix

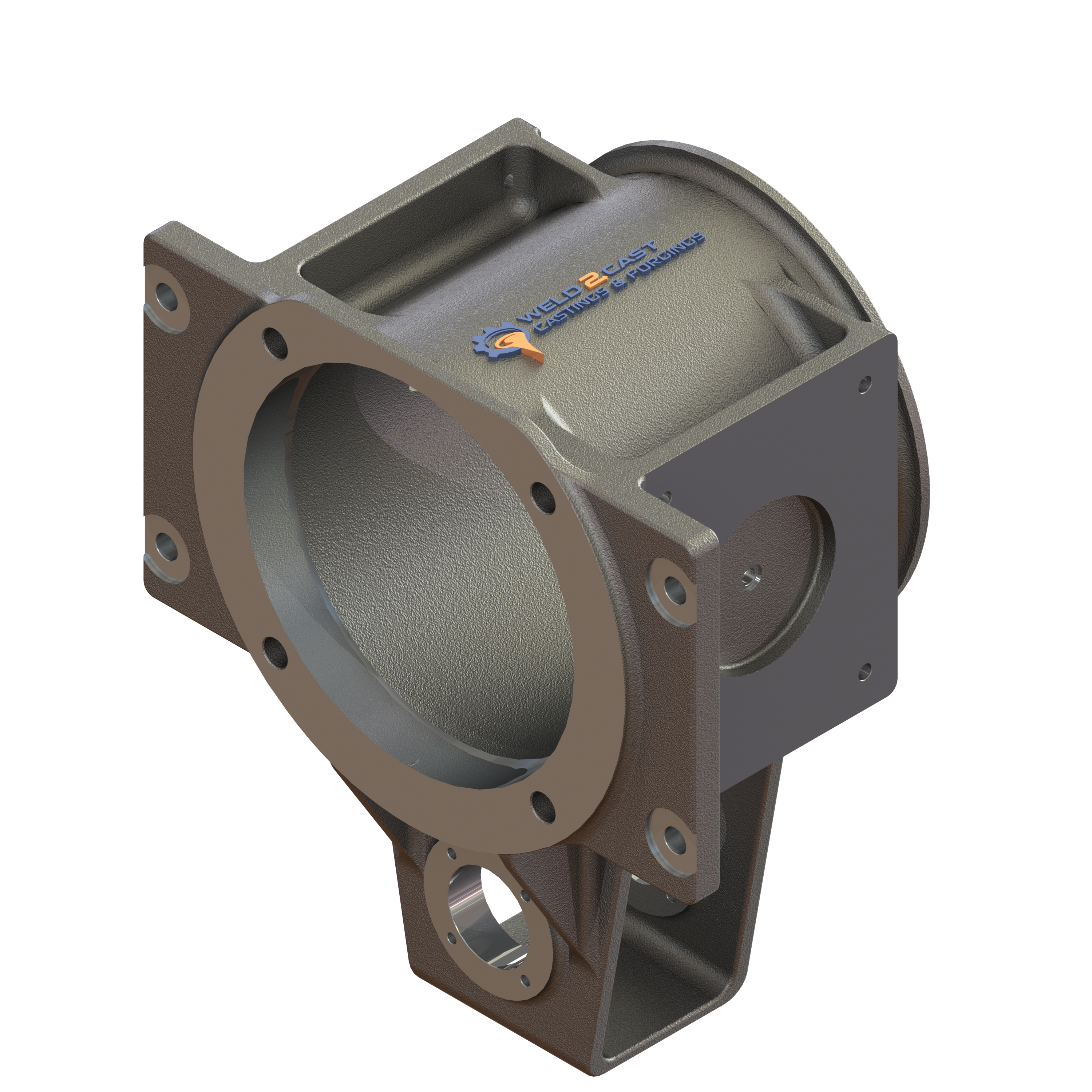

WELD2CAST’s Advantages and Resources For Your Engineered Castings.

WELD2CAST Engineering supplies a large range of finish machined and engineering components in different casting techniques such as Sand Casting, Investment Casting (Water Glass and Silica Sol), Shell Moulding, Gravity Die Casting, Lost Foam Casting, High-Pressure Die Casting and Sintering, all in many varieties of metal alloys.

We specialise in deliveries of engineered castings in small and medium quantities ranging in size from 0.05 kg/pcs. – 200 kg/pcs.

With our leadership’s 25 years of combined experience in casting, forging, CNC machining and surface treatments ensure we provide the best production methods in manufacturing products tailormade to your specific requirements.

| Sand Casting | Investment Casting (Water Glass ) | Investment Casting (Silica Sol) | Shell Moulding Casting | Gravity Die Casting | High-Pressure Die Casting | Lost Foam Casting | Sintering | |

| Metals | Ferrous and Non-Ferrous | Most Ferrous | Most Ferrous | Most Ferrous | Only Non-Ferrous | Only Non-Ferrous | Most Ferrous | Ferrous and Non-Ferrous |

| Size of Components | All Sizes | Small and medium | Small | Medium | Medium and big | Small and medium | Medium | Very small |

| Weight of Components (Kg) | 1(kg) - Many tonnes | 0,25 - 50 (kg) | 0,1 - 30 (kg) | 1 - 50 (kg) | 1 - 100 (kg) | 0,2 - 20 (kg) | 1 - 200 (kg) | 0,05 - 1 (kg) |

| Flexibility of design for conversion from weldments to castings | High | Very Excellent (WELD2CAST most popular method) | Excellent | High | Moderate | Relative high | High | Moderate |

| Production unit (pcs) | Suitable for very low and medium series | Suitable for low and medium series MOQ 50 pcs | Suitable for low and medium series MOQ 100 pcs | Suitable for low and medium series MOQ 300 pcs | Suitable for low and medium series MOQ 100 pcs | Suitable for medium and high series MOQ 1000 pcs | Suitable for medium series MOQ 500 - 1000 pcs | Suitable for high series MOQ 10 000 pcs |

| Cost of tooling/mould | Low (Starting at € 300) | Low (Starting at € 400) | Low (Starting at € 300) | Moderate (Starting at € 1000) | Low (Starting at € 300) | Moderate (Starting at € 1000) | High (Starting at € 1500) | Higher (Starting at € 5000) |

| Needs of secondary machining | High | Moderate | Low | Low | Moderate | Very Low | Low | None |

| Product manufacture cost | Low | Low | Medium | Medium | Low | Medium | Medium/High | Very High |

| Dimension casting tolerance acc. with ISO 8062 | CT10 - CT12 | CT7 - CT9 | CT4 - CT6 | CT7 - CT8 | CT7 - CT8 | CT4 - CT5 | CT7 - CT8 | CT1 - CT2 |

| Minimum of cast wall thickness | 6 - 8 mm | 4 - 5 mm | 2 mm | 5 mm | 4 mm | 2,5 mm | 3 mm | 3 - 4 mm |

| Draft angle need (deg ° ) | ± 2,0 ° | ± 1,0 ° | ± 0,5 ° | ± 1,0 ° | ± 1,0 ° | ± 0,5 ° | ± 1,5 ° | ± 0,1 ° |

| Surface finish (Ra) µ | Ra 50 µ | Ra 25 µ | Ra 3,2 µ | Ra 25 µ | Ra 12,5 µ | Ra 3,2 µ | Ra 25 µ | Ra 3,2 µ |

| Casting Alloys | Iron | Low-Alloy Steel | Low-Alloy Steel | Ductile Iron | Aluminium | Aluminium | Iron | Iron |

| Ductile Iron | High-Alloy Steel | High-Alloy Steel | ADI - (Austempered ductile iron) | Copper | Zinc | Ductile Iron | Low-Alloy Steel | |

| ADI - (Austempered ductile iron) | Stainless Steel | Stainless Steel | Low-Alloy Steel | Magnesium | ADI - (Austempered ductile iron) | High-Alloy Steel | ||

| Low-Alloy Steel | Hastelloy | Duplex Stainless Steel | High-Alloy Steel | Low-Alloy Steel | Magnesium | |||

| High-Alloy Steel | Titatium | Stainless Steel | High-Alloy Steel | |||||

| Stainless Steel | Duplex Stainless Steel | Copper | ||||||

| Aluminium | ||||||||

| Copper | ||||||||

| Bronze | ||||||||

| Sand Casting | Investment Casting (Water Glass ) | Investment Casting (Silica Sol) | Shell Moulding Casting | Gravity Die Casting | High-Pressure Die Casting | Lost Foam Casting | Sintering |

WELD2CAST’s castings are manufactured to international standards and specifications.

- EN/ISO 1561 – Gray cast irons

- EN/ISO 1563 – Spheroidal graphite cast iron

- EN/ISO 1564 or ISO 17804 – ADI (Aus tempered ductile iron)

- EN 10213 – Steel castings for pressure purposes

- EN 10283 – Corrosion resistant steel castings

- EN 10293 – Steel Castings for General Engineering Uses

- EN 1706 – Aluminium Castings Alloys.

- EN 1982 – Copper and copper alloys

All material qualities can be delivered with material certificate 3.1 or 3.2(EN 10204) with DNV, ABS, BV, GL or LR Approval.