Case studies

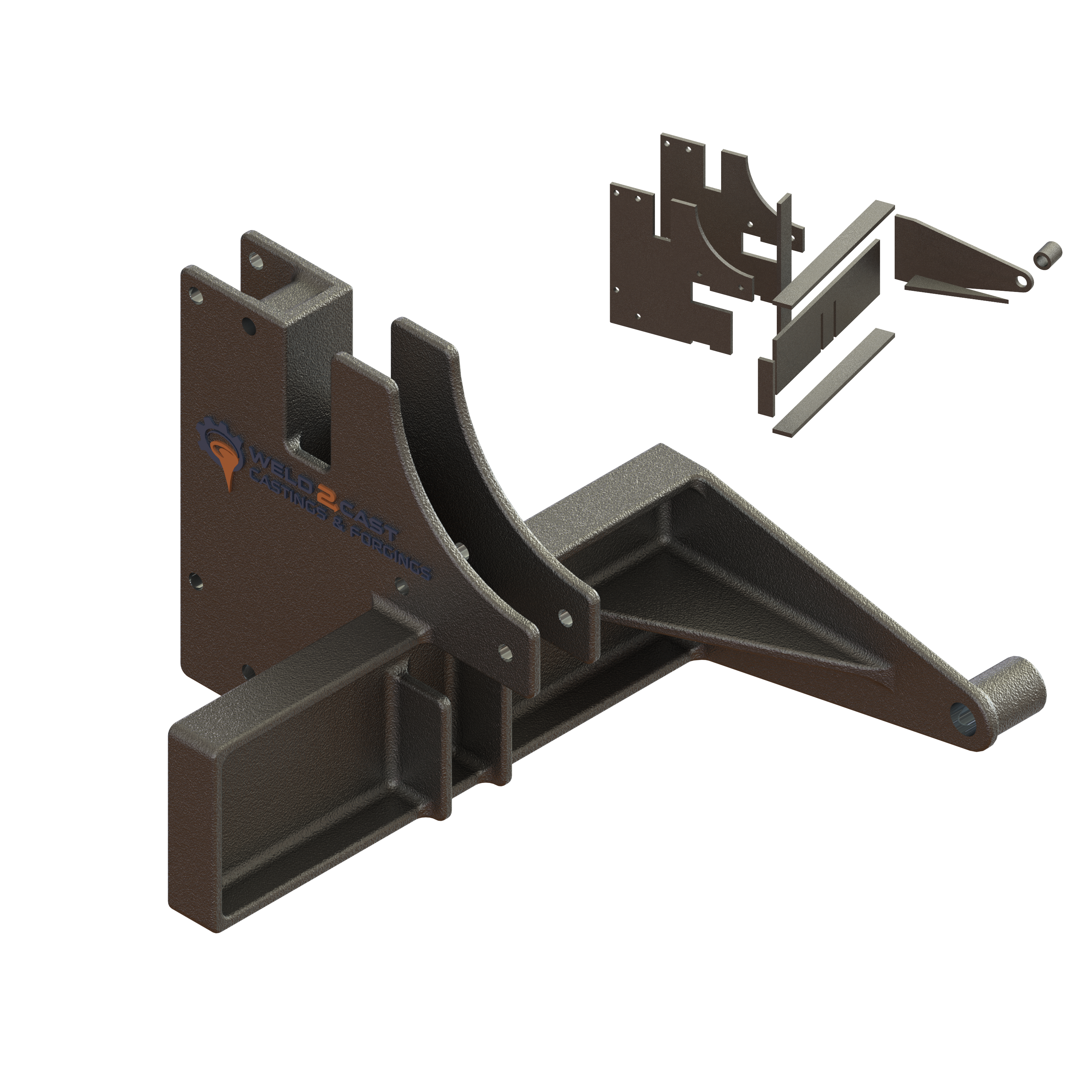

CASE STUDY NO. 1

Agricultural / Frame for lawnmower

Challange:

Conversion of 15-pieces Weldment to One-piece Casting Component

Engineering Outcome

- Weight reduction: - 22%

- Cost reduction: - 43%

- Strength Improvement: Min. + 29%

- Overall Product Efficiency: Min. + 50%

CASE STUDY NO. 2

Material Handling / Bracket for electric forklift

Challange:

Conversion of 11-pieces Weldment to One-piece Casting Component

Engineering Outcome

- Weight reduction: - 20%

- Cost reduction: - 29%

- Strength Improvement: Min. + 21 %

- Overall Product Efficiency: Min. + 40 %

CASE STUDY NO. 3

Machine Builder / Base Frame

Challange:

Conversion of 17-pieces Weldment to One-piece Casting Component

Engineering Outcome

- Weight reduction: - 17%

- Cost reduction: - 53%

- Strength Improvement : Min. + 30%

- Product Efficiency : Min. + 60%

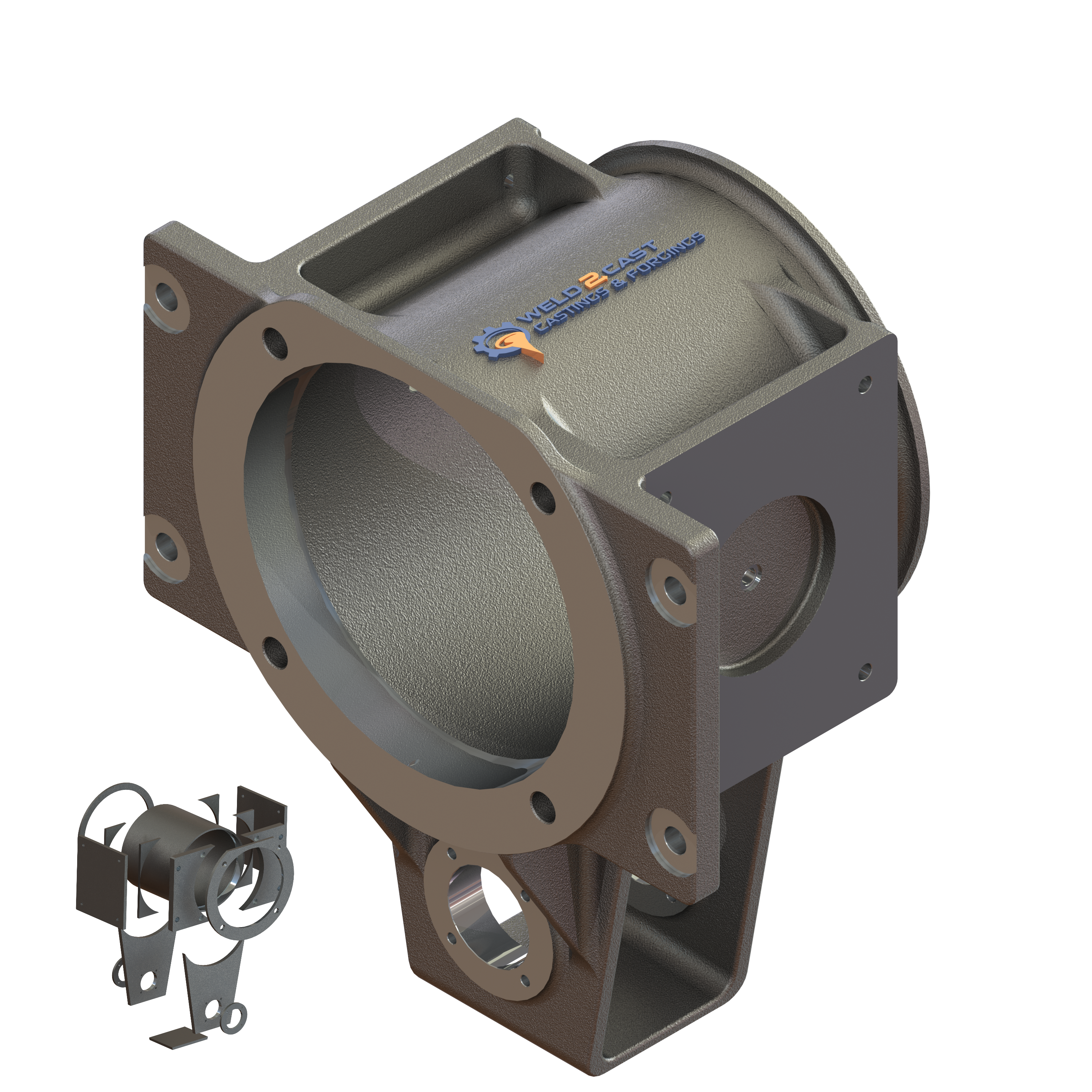

CASE STUDY NO. 4

Solar / Rotary adapter

Challange:

Conversion of 5-pieces Weldment to One-piece Casting Component

Engineering Outcome

- Weight reduction: - 32%

- Cost reduction: - 19%

- Strength Improvement : Min. + 29%

- Product Efficiency : Min. + 35%

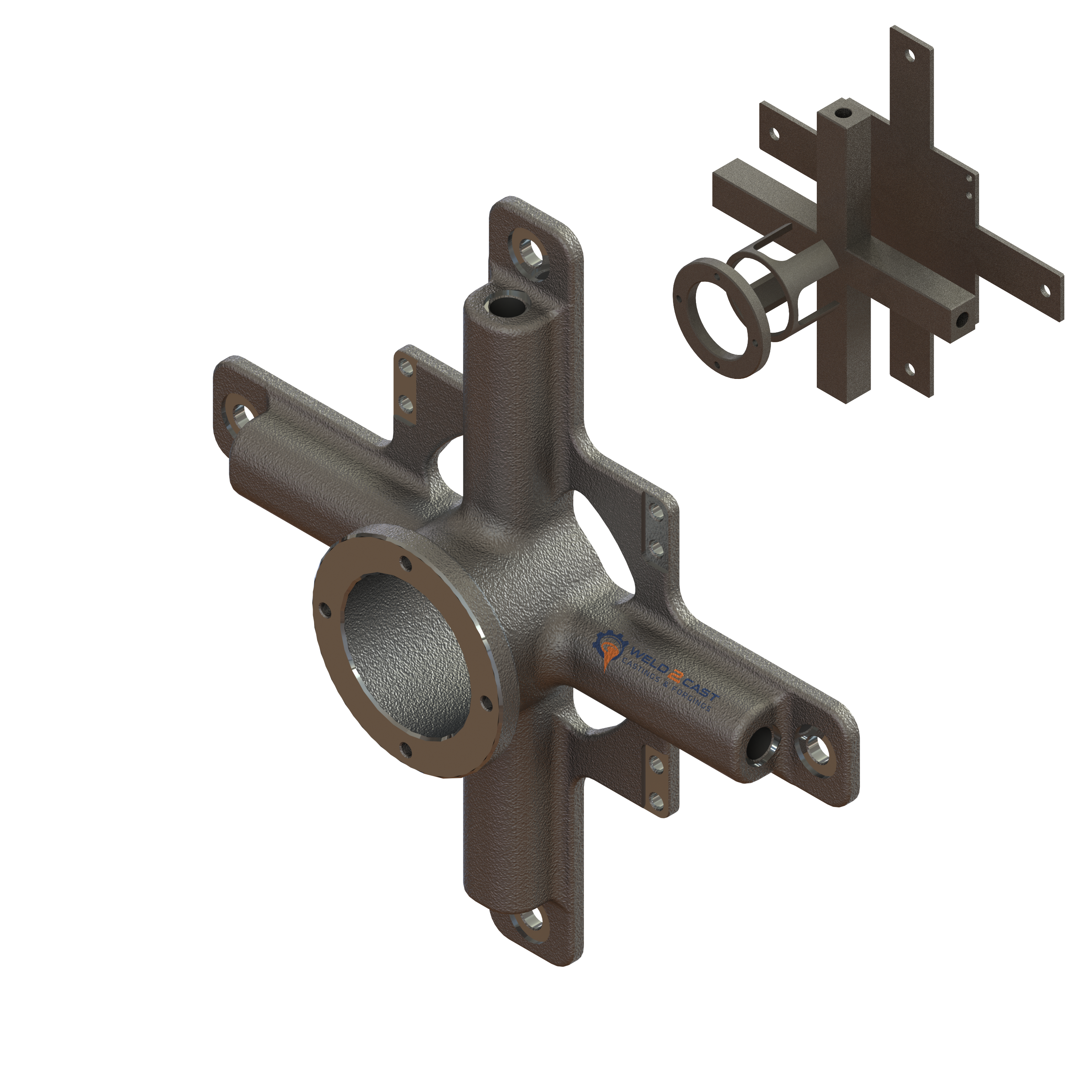

CASE STUDY NO. 5

Construction / Connector support

Challange:

Conversion of 11-pieces Weldment to a One-piece Casting Component

Engineering Outcome

- Weight reduction: - 14%

- Cost reduction: - 19%

- Strength Improvement : Min. + 25%

- Product Efficiency : Min. + 41%

CASE STUDY NO. 6

Agricultural / Arm for seeding machine

Challange:

Conversion of 13-pieces Weldment to One-piece Casting Component

Engineering Outcome

- Weight reduction: - 12%

- Cost reduction: - 57%

- Strength Improvement: Min. + 33%

- Product Efficiency: Min. + 71%