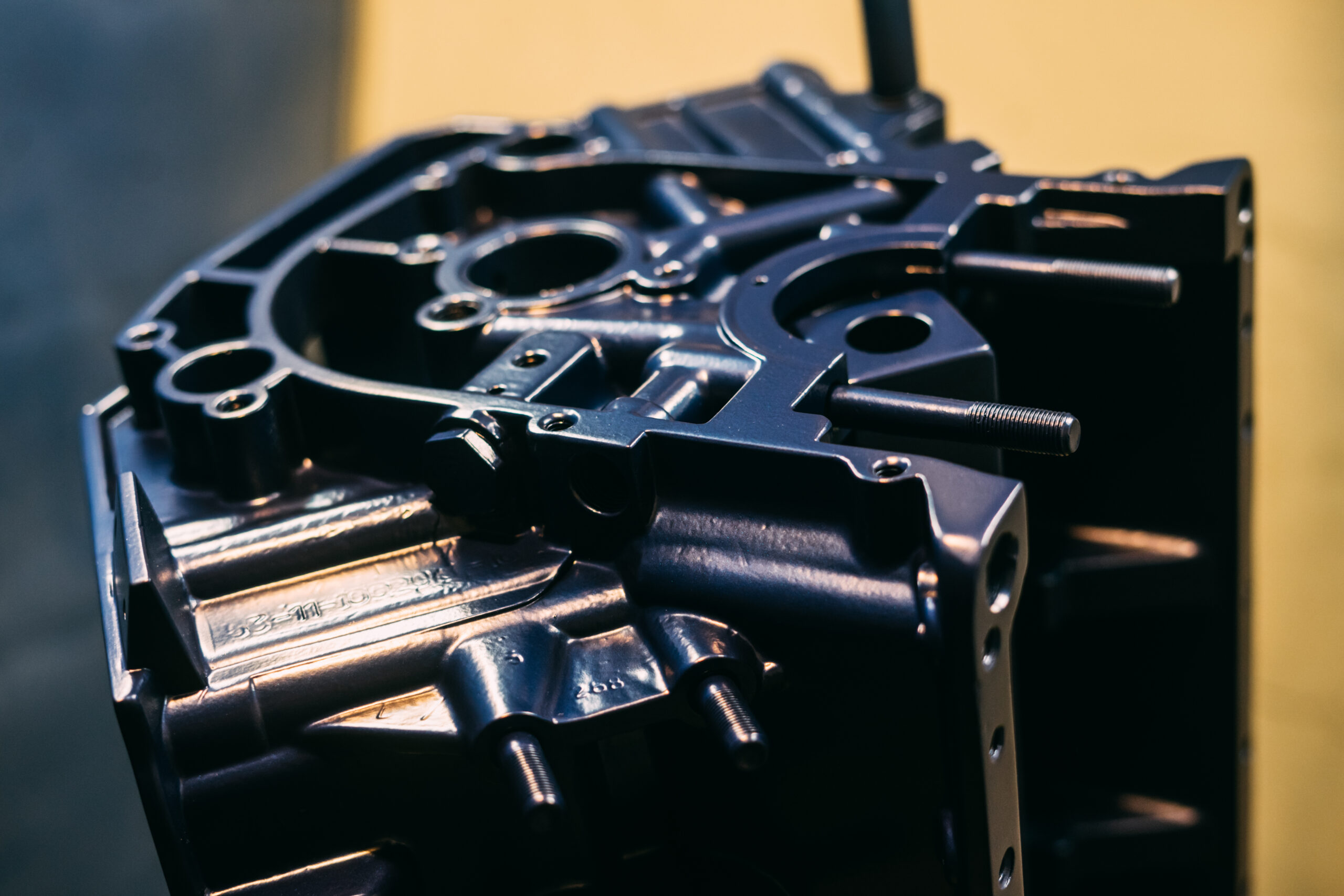

Surface Finishing

Let WELD2CAST Take Care Of The Surface-Finishing Process

WELD2CAST Engineering can offer several surface-finish options for your engineered CASTINGS and FORGINGS to suit our customers’ requirements.

We have longstanding relationships with our surface-finishing suppliers, working closely with them to ensure we maintain a stable and efficient supply chain so that our customers receive the smoothest possible service.

Take advantage of our one-source solution for all your surface treatment requirements.

WELD2CAST’s Many Surface Finishing Capabilities:

- Wet painting

- Powder coating

- EC-Coating (Electrodeposition coating)

- Electrolytic zinc plating

- Electrolytic zinc-iron alloy coating

- Electrolytic zinc-nickel plating (Zn, Ni) 12-15%

- Zinc flake (Geomet) / Dacromet 6µ,10µ and 12µ.

- Hot-dip galvanisation (HDG) acc. EN/ISO 1461

- Black oxide coating

- Anodising

- Passivation

- Chromating

- Polish and mirror polishing (Stainless and Aluminium castings)

- Corr-I-Dur

- Nitrocarburising

- Sand blasting and primer

All our Surface Treatments are RoHS compliant, and we can supply corrosion tests in artificial atmospheres. Salt spray tests (ISO 9227:2006).