Rubber & Silicone Components

Engineered Rubber and Silicone Components

WELD2CAST Engineering has increased our product range by adding customized molded rubber- & silicone components to the program, which is an addon and perfect match to our metal program.

Moulded rubber & silicone parts are produced in one pressing operation. Whether the process is press, transfer or injection moulding we find the best option depending on number of pieces, quality, economy, and geometry of the article.

Our material capabilities for Rubber and Silicone Components includes EPDM, NR, NBR, SBR, Viton, AEM, CR, Silicone, all in hardness in Shore from 20° – 90° and which is easy to design in color options.

General tolerances for Moulded Rubber & Silicone Components are supply acc. to ISO 3302-1:2014 – Class M1 M2 and M3. Tolerances are greatly affected by part geometry and type of material.

We offer our customer an “One Stop Solution” for all types of molded OEM-components. Together with metal parts, castings or forgings, we design and advise about gaskets, seals, plugs, membranes, buffer or dampers, for your complete product.

Your Key Advantages of WELD2CAST & RubiNord Combined Engineering Metal, Rubber & Silicone Solutions

- ONE Innovation Partner for ALL Your Engineering Metal and Rubber Components.

- High technical experience.

- Low tooling cost.

- Reduce total cost, better transparency, and improved flexibility.

- One specialist contact with skills and experience about your business, applications and needs.

- Reinsurance correct quality and correct product the first time.

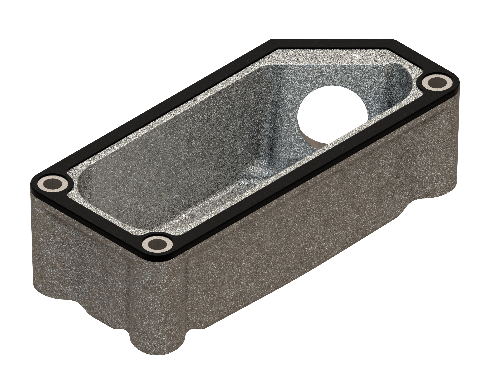

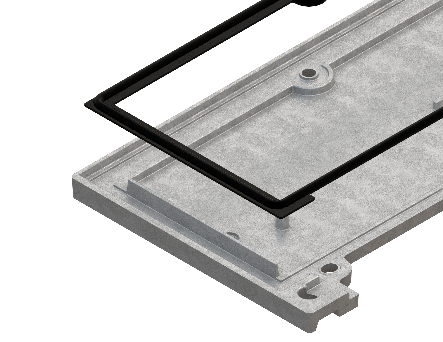

Case Study 1

Stainless Precision Casting Component supplied assembled with Injections Moulding EPDM Rubber Gasket

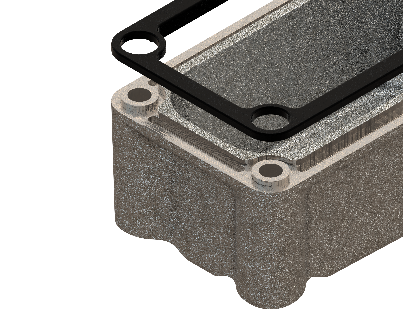

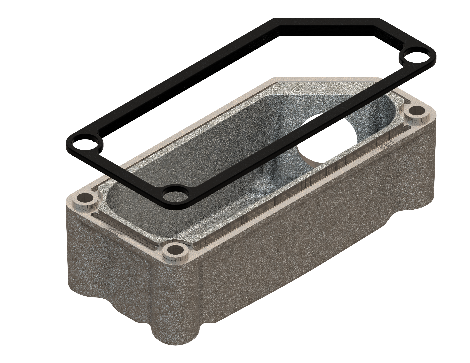

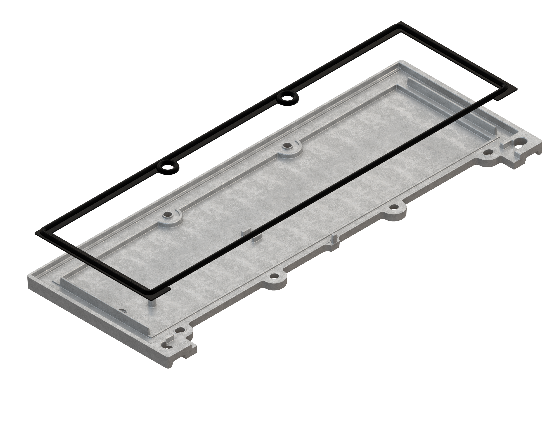

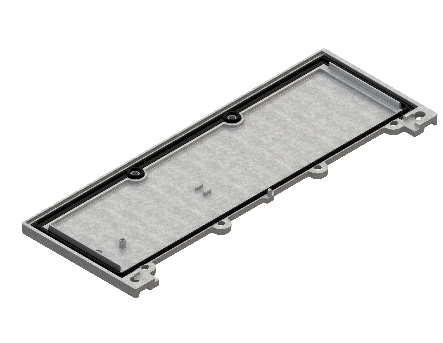

Case Study 2

High Pressure Die Castings Component supplied assembled with Injections Moulding EPDM Rubber Gasket